Waste Incineration in Cement Kilns

The cement industry is actively seeking to increase the use of alternative fuels for cement production. Both to decrease energy dependence on conventional fossil fuels and to mitigate negative environmental impact.

One of these alternatives is waste-to-energy. Many cement plants generate energy through the incineration of waste. Hazardous waste can be incinerated at specific waste-to-energy plants but also at plants with permission for co-incineration of waste.

The downside is that waste incineration in cement kilns releases toxic emissions into the air containing mercury, lead, cadmium and thallium, and other heavy metals.

Cement Plants’ Emissions Monitoring

Cement plants in general follow their own emissions monitoring standards. In cement plants, the flue gas generally includes carbon dioxide (CO2), nitrous oxides (NOx), sulphur dioxide (SO2), mercury and dust. SO2 emissions are mostly derived from the raw material, whereas more than half of the CO2 emissions are coming from the limestone calcination process and the rest are related to the used fuel and efficiency of the combustion process.

If a cement plant acts as a co-incineration plant and incinerates waste, it is subject to strict emissions regulations. All waste burning plants have to meet at least the stringent emissions limit, monitoring, waste reception and treatment standards brought in under the Waste Incineration Directive (2000/76/EC), which has been recast into the Industrial Emissions Directive (2010/75/EU).

The Waste Incineration Directive subjects co-incineration plants to the continuous measurement of for example hydrochloric acid (HCl), hydrogen fluoride (HF) and mercury (Hg). Measuring of total organic carbon (TOC) is also mandatory.

Our Solution: Monitoring Systems for Demanding Measurements

Both of our continuous emissions monitoring systems (CEMS) are certified systems designed for demanding emission monitoring measurements. We also have a sampling system for dioxin and furans.

- The Continuous Emissions Monitoring System CEMS II e offers TÜV and MCERTS certified solution (QAL1) for a wide range of demanding emission monitoring applications. The CEMS II e system utilizes Fourier Transform Infrared Spectroscopy FTIR technology. CEMS II e can also be equipped with a ZrO2 oxygen analyzer which is designed for continuous oxygen measurement of wet or dry flue gas. Gasmet CEMS II e is generally used to simultaneously measure the following 16 gases: H2O, CO2, CO, N2O, NO, NO2, SO2, HCl, HF, NH3, CH4, C2H6, C3H8, C2H4, C6H14 and CH2O.

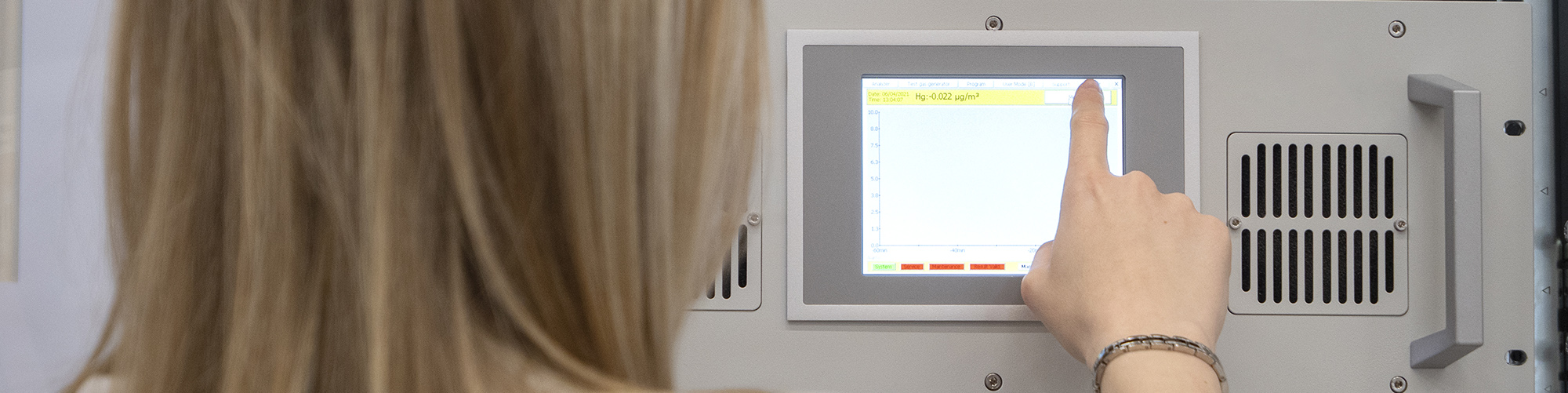

- The Continuous Mercury Monitoring systems CMM AutoQAL and CMM have the lowest certified range in the world (0-5 µg/m3). CMM AutoQAL has an automatic and integrated QAL3 validation tool. Systems are perfect for monitoring mercury continuously from hot, wet and corrosive gas streams. The systems utilizes Cold Vapor Atomic Fluorescence (CVAF) technology.

- The Dioxin Monitoring system GT90 Dioxin+ MCERTS certified device designed for long-term sampling of dioxin emissions and furans in conformity to the European standard EN1948-1 and EN15267. The system represents the cutting-edge technology for dioxin sampling and fulfills all the requirements of the dioxin measurement standard.

Why choose Gasmet as your emissions monitoring partner?

Gasmet is an ideal partner for the cement industry. Here are the top 5 reasons why you should choose us as your partner:

- Reduce risks with equipment that satisfy all regulatory requirements

- Save money with minimal maintenance, operational costs and calibration

- Gain longevity of investment with a long lifetime expectancy

- Future-proof your investment. With Gasmet’s solutions, if additional requirements emerge, new compounds can be added to the measurement setup without costly hardware changes.

- Gasmet has a reputation for providing analytical expertise, supplying quality products and services

Which Gasmet system best suits your emission monitoring needs?

Our Emission Monitoring Systems

Our products represent the pinnacle of what can be achieved in the measurement of gaseous emissions using automated measuring systems. We excel in manufacturing reliable, sensitive, and cost-effective continuous emission monitoring solutions that represent the future of gas analysis. We have a world-leading reputation, and we take pride in making sure all our current devices and future solutions are fully certified to the latest standards.